3D Printing in Orbit

Innovations for Exploration: 3D Printing in Orbit

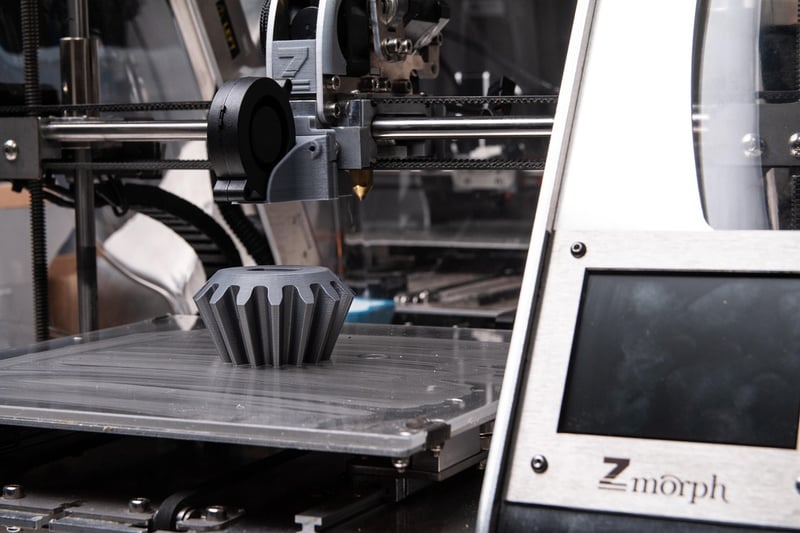

Exploring the vast unknown of space has always required cutting-edge technology and innovative solutions. One such groundbreaking technology that is revolutionizing space exploration is 3D printing in orbit. This cutting-edge technique enables astronauts to manufacture tools, replacement parts, and even entire structures right in space, significantly reducing the need for resupply missions from Earth. Let's delve into how 3D printing is changing the game for space exploration.

The Advantages of 3D Printing in Space

Traditional space missions have always been constrained by the limited storage capacity of spacecraft. Every tool, spare part, or component had to be carefully planned and packed before launch. However, with 3D printing capabilities on board, astronauts can now produce items on-demand, eliminating the need to carry every eventuality from Earth.

Moreover, the unique microgravity environment in space allows for the creation of intricate and complex structures that would be challenging or impossible to manufacture on Earth. This opens up new possibilities for designing lightweight yet robust components that can withstand the harsh conditions of space.

Applications of 3D Printing in Space Exploration

3D printing in orbit has a wide range of applications that can benefit space exploration missions. Some of the key applications include:

- Tool Manufacturing: Astronauts can quickly produce specialized tools tailored to specific tasks without waiting for a resupply mission.

- Replacement Parts: Instead of carrying an extensive inventory of spare parts, astronauts can simply print the components they need as they break or wear out.

- Structural Components: Building habitats, antennas, or other structures directly in space can streamline the construction process and reduce costs.

Challenges and Future Prospects

While 3D printing in orbit offers numerous advantages, there are still challenges to overcome. Ensuring the reliability and quality of printed parts, optimizing the printing process for different materials, and developing sustainable printing technologies are among the key areas of focus for future research and development.

Looking ahead, the integration of advanced materials, such as regolith-based composites or recycled plastics, could further enhance the capabilities of in-space manufacturing. As technology continues to evolve, 3D printing in orbit is poised to play a pivotal role in enabling long-duration space missions, sustainable lunar habitats, and ambitious crewed missions to Mars and beyond.

Conclusion

3D printing in orbit represents a significant leap forward in space exploration, offering unprecedented flexibility, efficiency, and self-sufficiency for astronauts on long-duration missions. By harnessing the power of this transformative technology, humanity can unlock new frontiers in space exploration and pave the way for a future where the stars are within reach.

Image Source: Pixabay